Model No.︰N NM-19

Brand Name︰Terblend N NM-19

Country of Origin︰Korea

Unit Price︰-

Minimum Order︰25 KG

Shanghai Ponci Trading Co., Ltd.

Mr.SU, +86 0 189 1805 1775 , SHBANGXI@126.COM ;

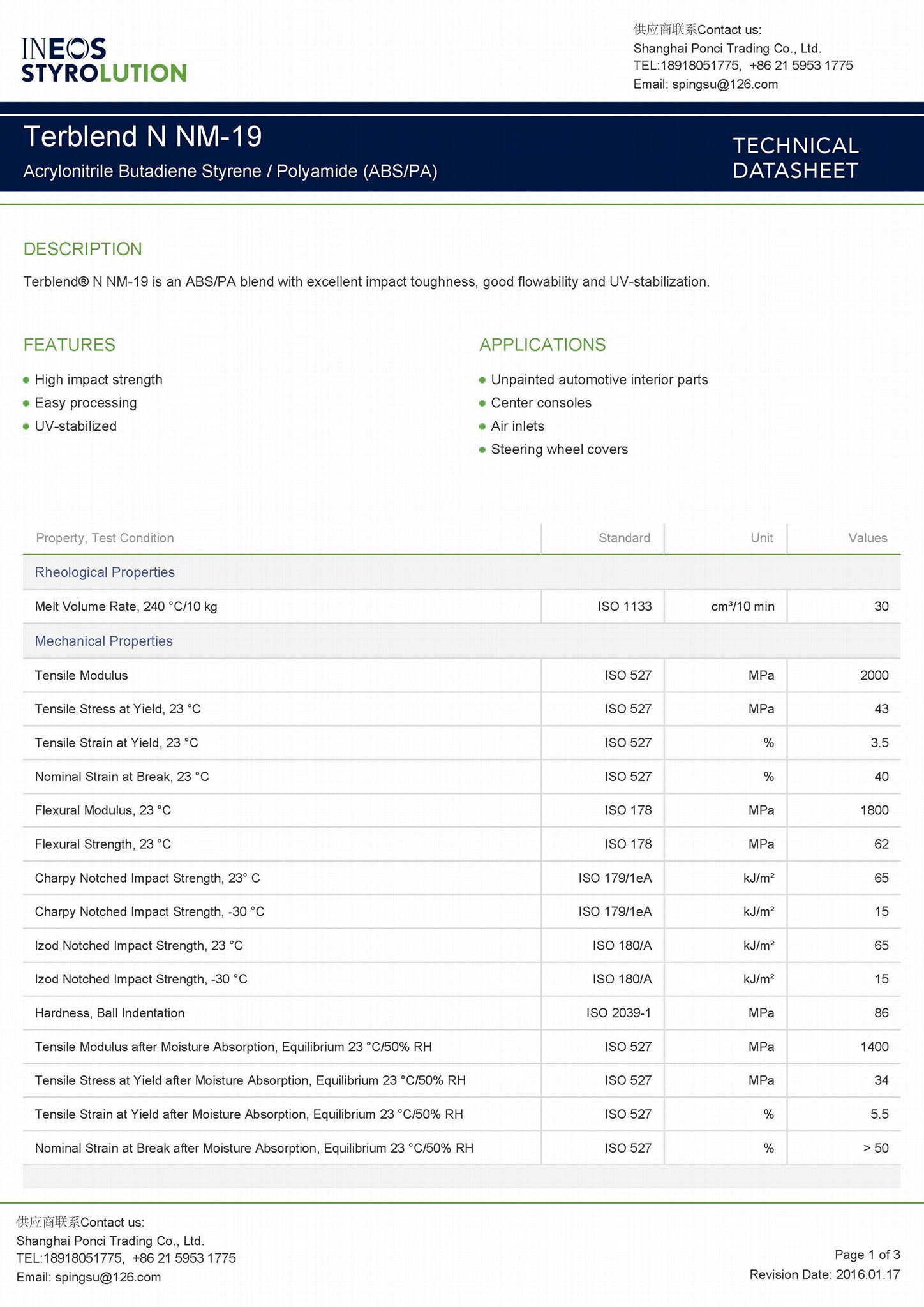

Terblend N NM-19

Terblend® N NM-19 is an ABS/PA blend with excellent impact toughness, good flowability and UV-stabilization.

Key Features

Applications

Industries

Terblend N NM-19 Properties

Mechanical Properties

Value & Unit

Test Condition

Test Method

Elongation at Break, MD

> 50 %

ISO 527-3

Tensile Modulus

2000 MPa

ISO 527

Tensile Strain

3.5 %

at Yield, 23°C

ISO 527-2

Flexural Strength

62 MPa

ISO 178

Flexural Modulus

1800 MPa

ISO 527

Impact Strength, Notched Charpy

65 kJ/m²

23°C

ISO 179

Hardness, Ball Indentation

86 MPa

ISO 2039-1

Impact Strength, Notched Charpy

15 kJ/m²

-30°C

ISO 179

Hardness, Rockwell

103 R Scale

ISO 2039-2

Tensile Strength, Yield

43 MPa

At 23°C

ISO 527-2

Thermal Properties

Value & Unit

Test Condition

Test Method

Heat Deflection Temperature (HDT), Annealed

85 °C

At 66 psi (0.45 Mpa)

ISO 75-2/B

CTE, Linear

100×10-6 /°C

ISO 11359

Vicat Softening Temperature

160 °C

VST/A/50 (50°C/h, 10N)

ASTM D1525

Vicat Softening Temperature

102 °C

VST/B/50 (50°C/h, 50N)

ISO 306

Heat Deflection Temperature (HDT), Annealed

65 °C

At 264 psi (1.80 Mpa)

ISO 75-2/A

Physical Properties

Value & Unit

Test Condition

Test Method

Melt Volume-Flow Rate (MVR)

30 cm³/10 min

240°C/10 kg

ISO 1133

Moisture Absorption at Equilibrium

1.2 %

50 % R.H

ISO 62

Density

1070 kg/m³

ISO 1183

Electrical Properties

Value & Unit

Test Condition

Test Method

Dissipation Factor

150

1 MHz

IEC 60250

Volume Resistivity

> 1.000E+013 ohm-m

IEC 60093

Relative Permittivity

2.9

1 MHz

IEC 60250

Surface Resistance

1E14 ohm

IEC 60093

Terblend® N NM-19 Processing Guidelines

Injection Molding Properties

Value & Unit

Test Condition

Test Method

Processing (Melt) Temp

240 - 270 °C

Linear Mold shrinkage

0.8 %

Mold Temperature

40 - 80 °C

Screw Length

18 - 23 D

Drying Temperature

80 - 90 °C

Length of Feed Section

0.5 - 0.55 l

Drying Time

4 hr

Length of Compression Section

0.25 - 0.3 l

Suggested Max Moisture

0.1 %

Length of Metering Section

0.2 l

Flight Depth in Feed Section

0.8 - 1.0 D

Flight Depth Ratio

2 - 3

Compression Ratio

2 - 2.5